views

How Does Grab Bucket Crane Works?

Single rope grab

A single rope grab on grab bucket crane is an excellent choice for transferring bulk materials. Its easy assembly and disassembly makes it ideal for all kinds of operations, including ground and underwater operations. In addition, it can be used with various types of cranes, including traveling cranes. Its features include its light weight, high grasping ratio, and high material loading rate. In addition, it can be controlled manually or via a remote control. This model is often used in port yards and other environments that require a quick transfer of materials.

The single rope grab on grab bucket crane is made up of steelcable drios and a lock. The open grab falls on materials as it catches them between the steelcable drios and the grab. Once the materials are caught, the steelcable drios lift the sliding mechanism to release the material from the grab and a locking mechanism slides down. The driver then re-lifts the grab.

Non-power self-supplied grab

The non-power self-supplied grab bucket crane is designed to reduce the need for external power. The invention includes a control system and a load sharing mechanism. These features help to prevent dropped objects during operations. The load sharing mechanism can be adjusted based on changes in the target's specific gravity and gripping characteristics.

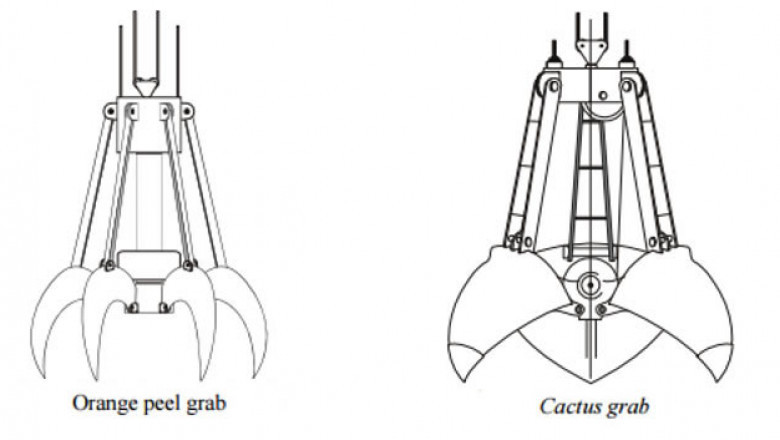

Grab bucket cranes are available in two basic types, mechanical rope grabs and electric motor grabs. The mechanical rope grab is available in single, double, and four-rope models. Electric motor-driven grabs are not suitable for working under water, so they are not commonly used for this kind of operation. Clamshell grab bucket cranes are most commonly used for work requiring loose deposits.

Straw bale grab

Straw bale grab is one of the material handling equipments that is used for unloading, stacking and feeding straw bales. Its high working efficiency and high mobility make it suitable for different types of warehouses. The main uses of this equipment are in power plants, wood yards and wharfs.

This crane is usually used for bulk materials and can be used both indoors and outdoors. Its total lifting capacity is 25 t. The size of the crane must be compatible with the weight of the goods to avoid damage to the goods. Also, it should be compatible with the type of goods being transported.

Timber grab

A timber grab bucket crane is a powerful tool for lifting and unloading logs. It is perfect for use in the woodyard, forestry center, or port. Its main components are the up and down bearing beam assembly, bearing bars, and wire rope, as well as a bucket unit. These components are connected by a hydraulic system made up of a motor, a hydraulic pump, and a coupling valve.

Timber grab bucket cranes come in a variety of configurations. Those that use a single set of traction mechanism will have one drum or a dual drum. The traction mechanism will vary depending on the application. Some types are equipped with hydraulic power, while others will use pneumatic motors.

Straw bale loader

Grab bucket crane manufacturers provide mechanical device that works with straw bale loader. It is a versatile tool for straw bale loading and discharging. It has several functions, including weighing and moisture detection. Moreover, it can work with cranes to lift bulk materials. This equipment is commonly used in coal mines, sand mills, and infrastructure construction. It can also be used to handle straw bales and other bulk materials.

It has two or more bucket jaws that open and close to grab bulk materials. The material is then caught in the gap and scattered on a pile. The crane's wire rope is used to move the jaws.