views

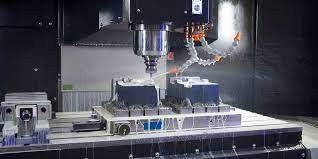

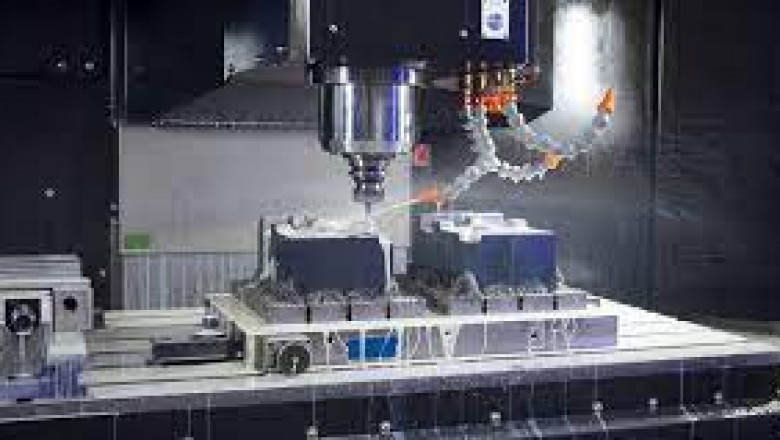

What is the machining allowance?

The machining allowance is the amount of material that can be removed while the part is being machined. It is usually specified in inches, but can also be specified in millimeters or degrees. The allowance is important because it determines how much material the machine can remove without affecting the part's shape.

How do you determine the machining allowance?

To be able to determine the machining allowance, you should consider the factors like materials, size, accuracy grade and machining method used.

There are a few reasons why the casting process should have a certain machining allowance.

-The casting may require special milling or drilling to ensure accuracy.

-The casting may be delicate and will require special care when being machined.

-The casting may have unique features that need to be considered when machining.

When is it necessary to have a machining allowance?

There are many reasons why it is necessary to have a machining allowance. In some cases, the allowance is needed to ensure that the parts that are being machined are within the manufacturer's specifications. In other cases, a machining allowance may be necessary to account for variations in the size and shape of the parts that are being machined. A machining allowance may be necessary to ensure adequate tool life. Ultimately, the decision as to whether or not a machining allowance is necessary will depend on the specific circumstances involved in each particular project.

To determine whether or not a machining allowance is necessary, first determine what the manufacturer's specifications are for the parts that are being machined. If the parts do not fall within the manufacturer's specifications, then it may be necessary to calculate an allowance based on the expected variations in size and shape of the parts. To calculate an allowance for tool life, first determine how often the tools will need to be replaced and then add an extra margin of safety to account for any unforeseen wear or tear. Ultimately, it is important to consult with a qualified engineer to make sure that all of the components of a project are properly dimensioned.